Unleashing Strength, Crafting Excellence.

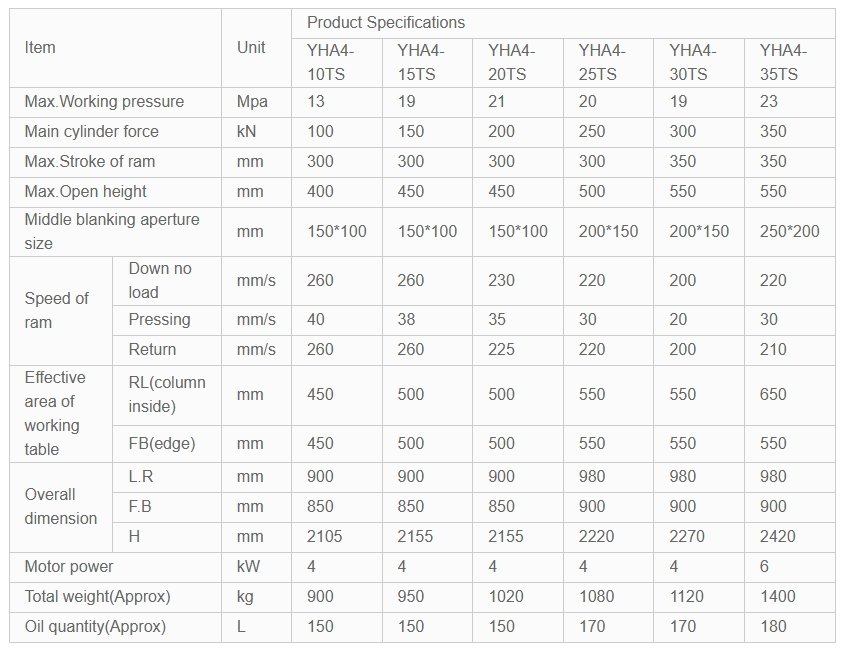

Trimming Hydraulic Press

For more customized requirements, please contact us

Technical Features and Applications of SUMHONG Trimming Hydraulic Press

Technical Features

- High-Speed Cylinder:

- Efficient Operation: Equipped with a built-in high-speed cylinder for rapid falling speeds and increased production efficiency.

- Durable Construction:

- High-Strength Columns: Four columns made from high-strength alloy steel with a hard chrome-plated surface for superior abrasion resistance.

- Adjustable Settings:

- Customizable Parameters: Pressure, stroke, and pressurizing time can be easily adjusted to meet specific processing requirements.

- Optional Configurations:

- Enhanced Features: Includes protective shields, anti-drop devices, scrap removal systems, LED lighting, and infrared grating for improved functionality and safety.

Applicable Scope

SUMHONG Hydraulic Press is versatile and suitable for:

- Die Casting Operations:

- Vents Trimming and Shaping: Ideal for aluminum alloy and magnesium alloy die castings.

- Industry Applications:

- Mobile Phones: Widely used in manufacturing aluminum and magnesium alloy components for mobile phones.

- Automotive and Motorcycle Parts: Effective for die casting parts in the automotive and motorcycle industries.

- Metal and Non-Metal Parts:

- Shaping and Punching: Suitable for various metal and non-metal components.

- Blanking Operations:

- Center and Side Blanking: Efficient for blanking operations.

- Automation:

- Robotic Integration: Compatible with automatic robots for operation on large worktable machines.