Unleashing Strength, Crafting Excellence.

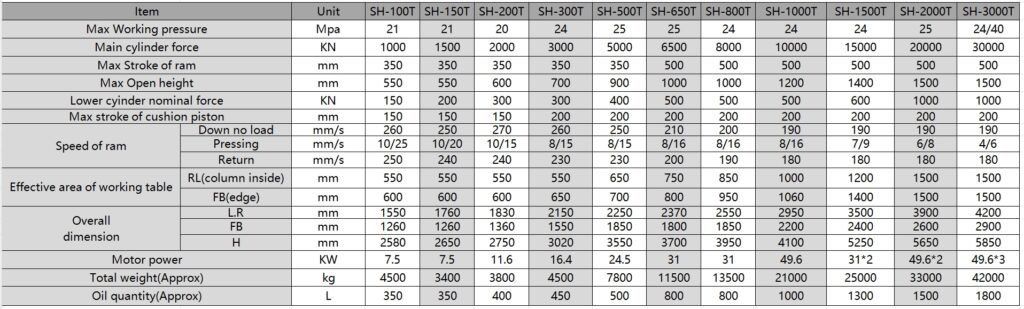

Rail Type Cold Extrusion Hot Forging Machine

For more customized requirements, please contact us

Discover the outstanding features of SUMHONG Rail Type Cold Extrusion Hot Forging Machine, engineered for precision and efficiency:

Advantages of SUMHONG Hydraulic Press

- Oil Leakage Prevention: The use of a servo motor reduces oil temperature, effectively preventing oil leakage.

- Bilingual Operation Interface: The system offers both English and the local language, making it easy to operate.

- Energy Efficiency: Saves 50% – 70% electricity compared to non-servo systems.

- Adjustable Parameters and Speed: Parameters and speed can be adjusted via the touch screen for easy operation. Non-servo machines lack this capability.

- Extended Service Life: Offers 3 to 5 years longer service life than common machines, potentially reaching up to 15 years.

- Enhanced Safety and Maintenance: Features automatic alarm and troubleshooting systems for easy error detection and after-service.

- Quick Mold Changes: Memory function enables quicker mold changes, eliminating the need for parameter adjustments with original molds.

- Quiet Operation: Operates very quietly without noise.

- Stability: Provides greater stability compared to common machines.

- High Precision: Achieves higher precision than standard machines.

Comprehensive Solutions:

- Full Production Line Service: Supplies custom machines, molds, robot arms (manipulators), auto feeders, and related machinery.

- Quality Components: Main components are imported from Japan and Taiwan, ensuring high quality at a lower cost compared to Japanese products.

- Specialized Manufacturing: With over 20 years of independent development and production, our hydraulic presses are stable and high-quality.

- Robust Structure: Uses a bending structure for the machine body, which is stronger than common welding structures.

- Leak-Proof Oil Pipes: Employs a clip-on structure for oil pipes, providing a tighter seal than welding structures to prevent oil leakage.

- Integrated Oil Manifold Block: Makes machine inspection and repair easier.

Quality Control:

All hydraulic presses from our factory have passed CE, ISO, SGS, and BV certifications.

Technical Features:

- Advanced Hydraulic System: Utilizes Taiwan’s advanced hydraulic system for more steady, safer, and reliable operations.

- Adjustable Parameters: Pressure, stroke, and pressure keeping can be adjusted according to processing requirements.

- High-Strength Columns: Four columns made of high-strength alloy steel with a hard chrome-plated surface for good abrasion resistance.

- Optional Ejecting Cylinder: The moving bolster and worktable are equipped with an optional ejecting cylinder to meet different product requirements.

- Digital Control: Achieved with PLC programming circuit design and touch panel operating system.