Unleashing Strength, Crafting Excellence.

Fully automatic mechanical powder compacting press

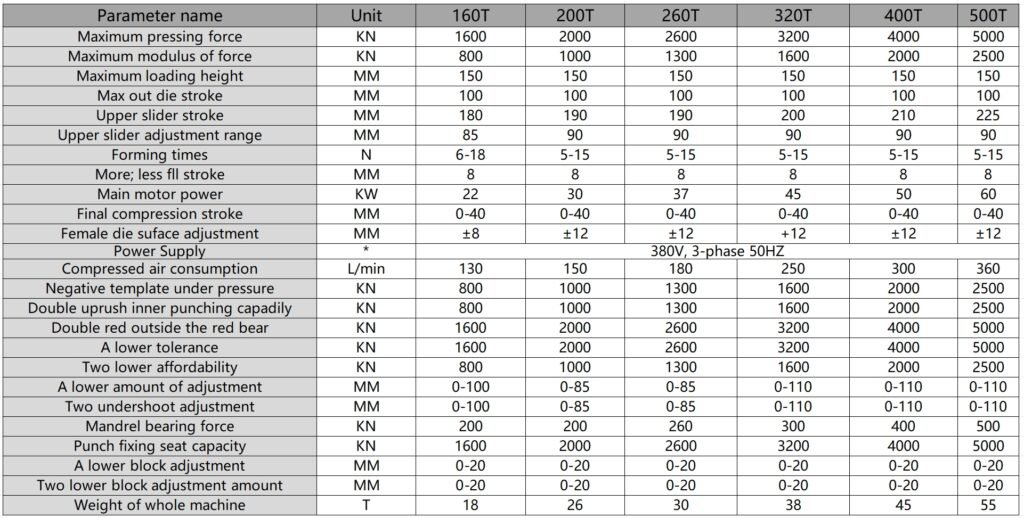

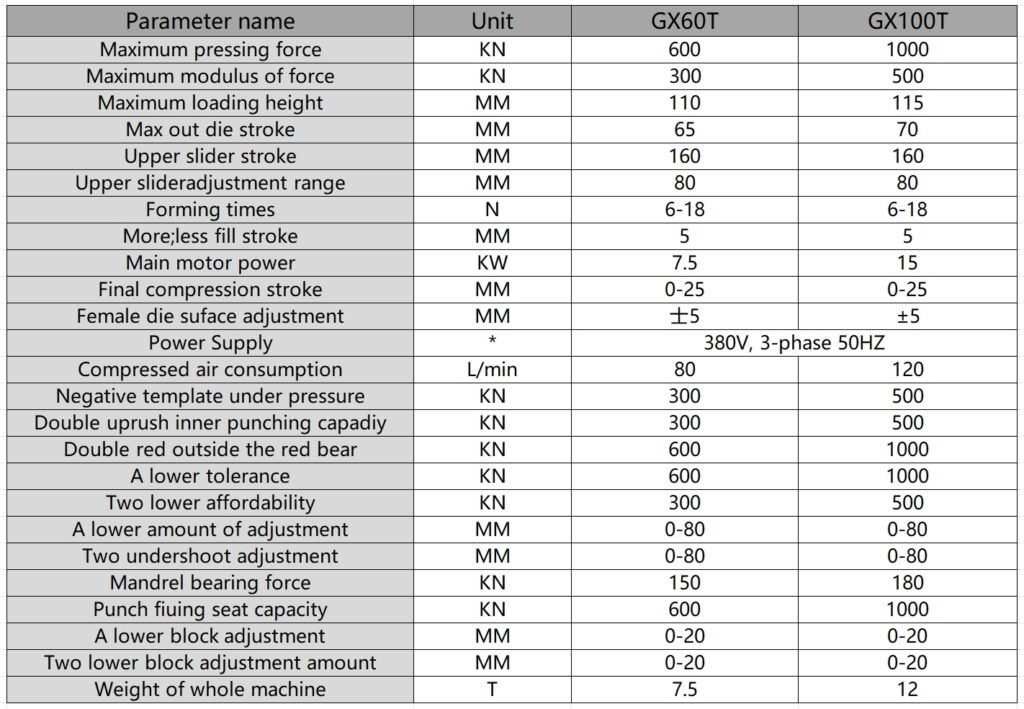

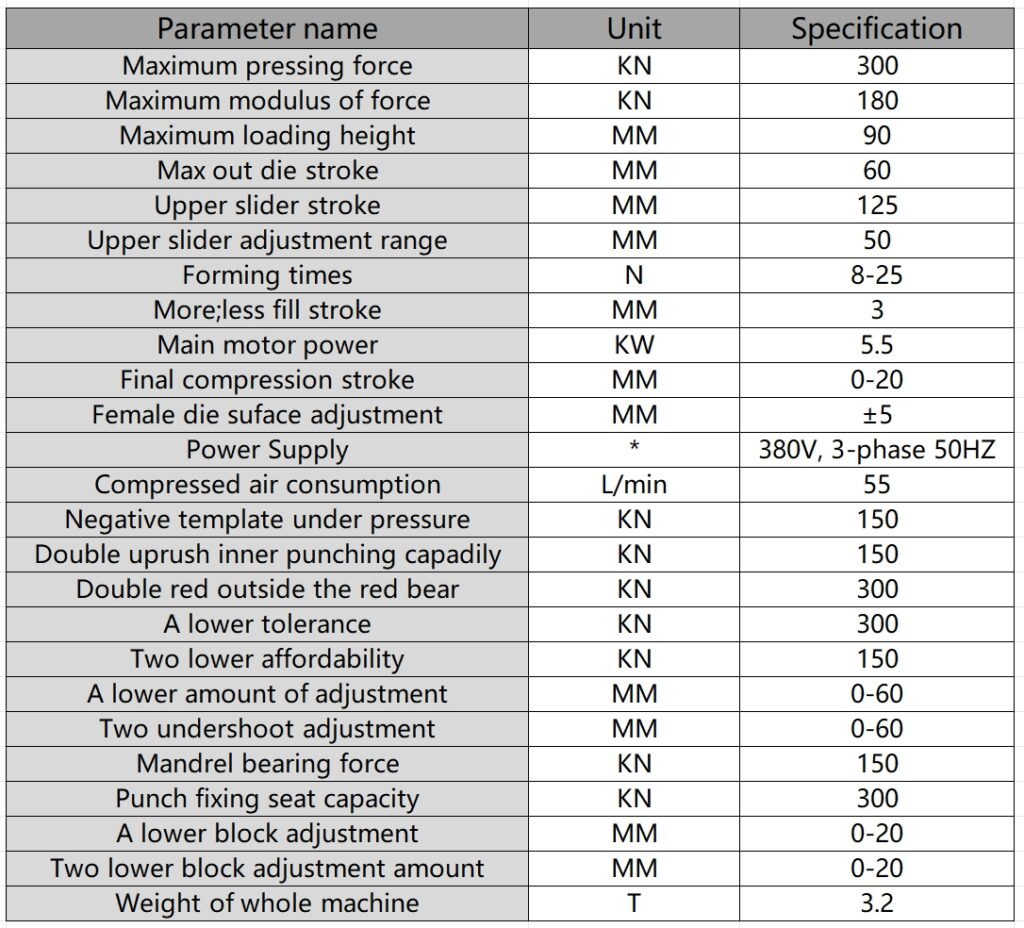

For more customized requirements, please contact us

Discover the outstanding features of SUMHONG fully automatic mechanical powder compacting press, engineered for precision and efficiency:

Features

Advanced Touch Screen Operation: Our electrical cabinets feature state-of-the-art computer touch screen operation, enabling seamless human-machine interaction. This allows for automatic adjustments of various functions, all centrally controlled by the computer. With the capability to store and recall process data for over 100 products, our system simplifies operation and reduces labor intensity.

Innovative C-Type Mold Base: The new C-type mold base (two upper, three lower) allows mechanical adjustments for the inner and outer sides of the double upper punches. The comprehensive filling mechanism compensates for molding defects in complex or specially-shaped pressed parts, ensuring high-quality results. (Special configurations with three upper and four lower mold bases are available if required.)

Comprehensive Filling Mechanism and Pressure Adjustment: The integrated filling mechanism and pressing pressure adjustment device maintain complex shapes and ensure optimal pressing effects. This system implements initial pressure (upper punch insertion) and two-way pressing, with upper punch pressurization and female mold floating. Both the female mold and lower punches can float, followed by pressurization and ejection. Parts are produced using a robot with automatic powder loading.

Fixed Mold Ejection and Loading Positions: The mold ejection and loading positions are fixed, ensuring consistent and reliable operation.