Unleashing Strength, Crafting Excellence.

Four Column Forging Hydraulic Press

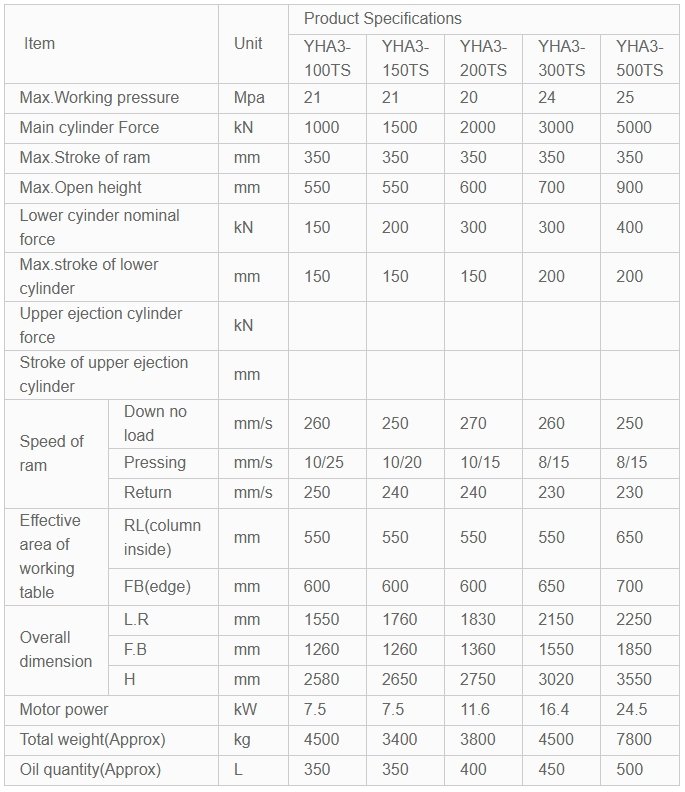

For more customized requirements, please contact us

Discover the Advantages of SUMHONG Four Column Forging Hydraulic Press with Servo System

- Imported Parts: Main components are sourced from Japan and Taiwan, ensuring quality comparable to Japanese production at a more competitive price.

- Robust Structure: Our machine body utilizes a bending structure, offering greater strength compared to common welding structures.

- Leak-Proof Design: Clip-on oil pipes provide a tighter seal than traditional welding structures, preventing oil leakage.

- Integrated Oil Manifold Block: Simplifies machine maintenance and repairs.

SUMHONG Hydraulic Press with Servo System offers numerous benefits that enhance performance, efficiency, and longevity. Here are ten key advantages:

- Prevents Oil Leakage: The servo motor technology helps lower oil temperatures, significantly reducing the risk of oil leakage.

- User-Friendly Interface: The machine features a bilingual operation interface in English and the local language, making it easy to operate.

- Energy Efficiency: Save 50% – 70% on electricity costs compared to traditional hydraulic presses.

- Adjustable Parameters: Speed and other parameters can be easily adjusted via the touch screen, a feature not available on machines without a servo system.

- Extended Service Life: Enjoy up to 5 additional years of service life. While standard machines last around 10 years, our servo-driven press can last up to 15 years.

- Enhanced Safety and Maintenance: Automatic alarm and troubleshooting systems make it easier to identify errors and perform maintenance.

- Quick Mold Changes: The memory function allows for quick mold changes without the need to re-adjust parameters.

- Quiet Operation: Experience a much quieter machine compared to conventional models.

- Stability and Precision: The servo system provides superior stability and high precision, surpassing traditional machines.

- Comprehensive Production Solutions: SOMHONG offers not just custom hydraulic presses, molds, robot arms (manipulators), and auto feeder process technology, but also a complete production line service.

High-Quality Components

Quality Assurance

Our hydraulic presses are certified by CE, ISO, SGS, and BV, guaranteeing high standards of quality.

Technical Features

- Advanced Hydraulic System: Utilizes Taiwan’s advanced hydraulic system for enhanced stability, safety, and reliability.

- Adjustable Pressure and Stroke: Customize pressure, stroke, and pressure holding according to your processing needs.

- Durable Columns: Four columns made from high-strength alloy steel with hard chrome plating for superior abrasion resistance.

- Optional Ejecting Cylinder: Tailored ejecting solutions for different product requirements.

- Digital Control: PLC programming and touch panel operation for precise control.

Applications

- Cold Extrusion Molding and Stamping: Ideal for auto parts, LED heat sinks, and hardware tools.

- Shallow Stretching and Molding: Suitable for both metal and non-metal parts.

High-Speed Hydraulic Press YH-FAST System

- Extruding Height Over 50MM: Features fast falling and a variable speed from fast to slow.

- Accumulator Release: Efficiently stores and releases energy to improve pressing speed and production efficiency.